A Comprehensive Guide to Laser Cutting

How Does Laser Cutting Work?

For years, laser cutting has profoundly impacted various industries with its remarkable precision, speed, and versatility. But have you ever wondered about the intricate mechanics behind this powerful technology? This article delves into the fundamental principles of laser cutting, covering key components like the laser source and laser cutting head, the process itself, essential software, and crucial safety protocols.

By understanding the science behind laser cutting, you can unlock its incredible potential for both large-scale industrial applications and bespoke creative projects. If you want to know how this innovative technology works, continue reading this in-depth guide.

How Do Lasers Precisely Cut Materials?

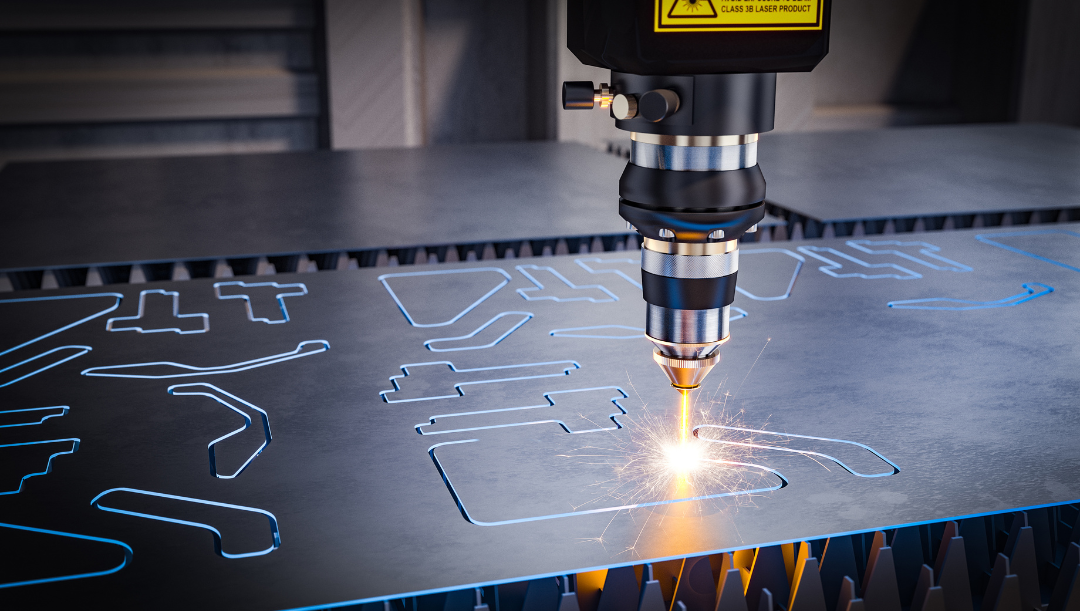

At its core, laser cutting works by directing a focused, high-intensity laser beam onto a material’s surface. This concentrated energy rapidly heats the material, causing it to melt, vaporize, or burn away along a predetermined path. Sophisticated control systems precisely guide the movement of the laser beam, while an assist gas system may be employed to evacuate molten material and debris, ensuring clean, sharp edges and superior cut quality.

Key Components of a Laser Cutting Machine

An Industrial Laser Cutting Machine is an integrated system comprising several critical components:

- Laser Source: The laser source is the heart of the machine, acting as the “powerhouse” that generates the high-intensity laser beam. Fiber laser sources, in particular, are highly regarded for their superior efficiency, extended service life, minimal maintenance requirements, and lower operating costs.

- Laser Optics: These precision-engineered optical components—including mirrors and lenses—shape, direct, and focus the laser beam with exceptional accuracy onto the target material. The quality and integrity of the laser optics are paramount to achieving the desired cut precision and quality in any laser processing application.

- Laser Cutting Head: The laser cutting head is a pivotal component responsible for delivering the focused laser beam directly to the workpiece. It houses key parts such as the nozzle, focusing lens, and a focus-tracking system. This assembly travels along the pre-programmed cutting path, with its height precisely adjusted to accommodate different material types, thicknesses, and cutting parameters.

- Laser Cutting Control System: This is the intelligent brain of the laser cutting machine, meticulously managing and regulating all functions to ensure precise and efficient cutting operations. The control system, consisting of both hardware and software, orchestrates the performance of the laser source, the beam delivery system, and the laser cutting head.

- Assist Gas System: To enhance the cutting process, many laser cutting machines utilize assist gases like oxygen, nitrogen, or compressed air. The assist gas system precisely controls the flow rate and pressure, effectively blowing away molten material and debris from the cutting kerf, thereby preventing re-solidification and improving the cut quality.

The Laser Cutting Process: A Step-by-Step Breakdown

The laser cutting process is a seamless workflow, from design to final product:

- Design Preparation: The process begins with creating a design using computer-aided design (CAD) software. This digital blueprint defines the exact shape, dimensions, and cut paths, providing precise instructions for the laser to follow.

- Material Setup: The raw material is securely positioned on the laser cutter’s bed, often using clamps or a vacuum table to ensure stability and accuracy. It is crucial to ensure the material surface is clean and free of contaminants that could interfere with the laser beam.

- Laser Beam Emission: The machine settings for power, speed, and focus are meticulously configured based on the specific material and its thickness. The high-powered laser beam is then emitted from the laser source and guided through the laser optics to the material surface.

- Material Cutting: As the laser beam makes contact, it instantly melts, vaporizes, or burns the material along the designated cutting path. The control system precisely moves the laser cutting head to follow the digital design file with exceptional accuracy.

- Cooling and Finishing: An assist gas is often used to clear molten material, preventing dross and ensuring a clean cut. Once cutting is complete, the part is removed from the machine, and any necessary post-processing steps are performed.

Software Options for Laser Cutting

Choosing the right software is vital for preparing files for laser cutting:

- CAD/CAM Software: Computer-aided design (CAD) and computer-aided manufacturing (CAM) software are the industry standard for creating and preparing designs. These platforms streamline the entire manufacturing process, from conceptualization to toolpath generation, enhancing efficiency and accuracy.

- AutoCAD: This widely used CAD software allows for the creation of precise 2D and 3D designs. Designs can be easily exported in formats like DXF or DWG, which are compatible with most laser cutters.

- Adobe Illustrator: As a leading vector graphics editor, Adobe Illustrator offers an intuitive interface and a powerful toolset for creating intricate designs. It supports various file formats, including SVG, PDF, and EPS, making it a versatile choice for designers.

- Inkscape: A free and open-source alternative, Inkscape provides robust tools and features that compete with commercial software. Its native support for Scalable Vector Graphics (SVG) ensures seamless integration with laser cutting workflows.

Understanding Laser Cutting Safety

Operating a laser cutting machine requires strict adherence to safety protocols to mitigate risks:

- Safety Glasses: Eye protection is non-negotiable. Specialized laser safety glasses are essential to filter out harmful wavelengths and prevent severe and permanent eye injuries.

- Protective Clothing: Operators must wear non-flammable, long-sleeved shirts and pants to protect exposed skin from burns caused by high-intensity laser beams.

- Ventilation System: Laser cutting generates hazardous fumes and particles. A proper ventilation and exhaust system is critical to remove these contaminants, ensuring a safe and clean working environment.

- Fire Safety: Laser cutting machines can pose a fire risk if not managed correctly. Implementing strict safety protocols and constant supervision are essential to prevent fire hazards.

- Operator Training: Comprehensive training is paramount. Operators must possess the necessary knowledge and skills to operate the equipment safely and efficiently.

- Material Compatibility: Only approved materials should be used. Certain materials can produce toxic fumes or dangerous reactions when cut with a laser.

Summary

Laser cutting is a precise and highly adaptable process that harnesses the power of focused light to achieve remarkable accuracy and versatility. By utilizing advanced software and state-of-the-art technology, it enables the execution of intricate designs with unparalleled precision. However, to fully capitalize on its potential, prioritizing safety must always be a core principle.