Choosing the Right Vertical Machining Center for Your Production Needs

Choosing the right vertical machining center (VMC) is key for precision machining. It helps ensure high-quality results and smooth production. No matter if you run a small shop or a big manufacturing unit, knowing the basics of VMCs is important. This is especially true for the CNC double column vertical machining center. It can help you make smart choices. This article looks at what makes a VMC right for you. We’ll also discuss how to improve your production processes.

Understanding the Vertical Machining Center (VMC):

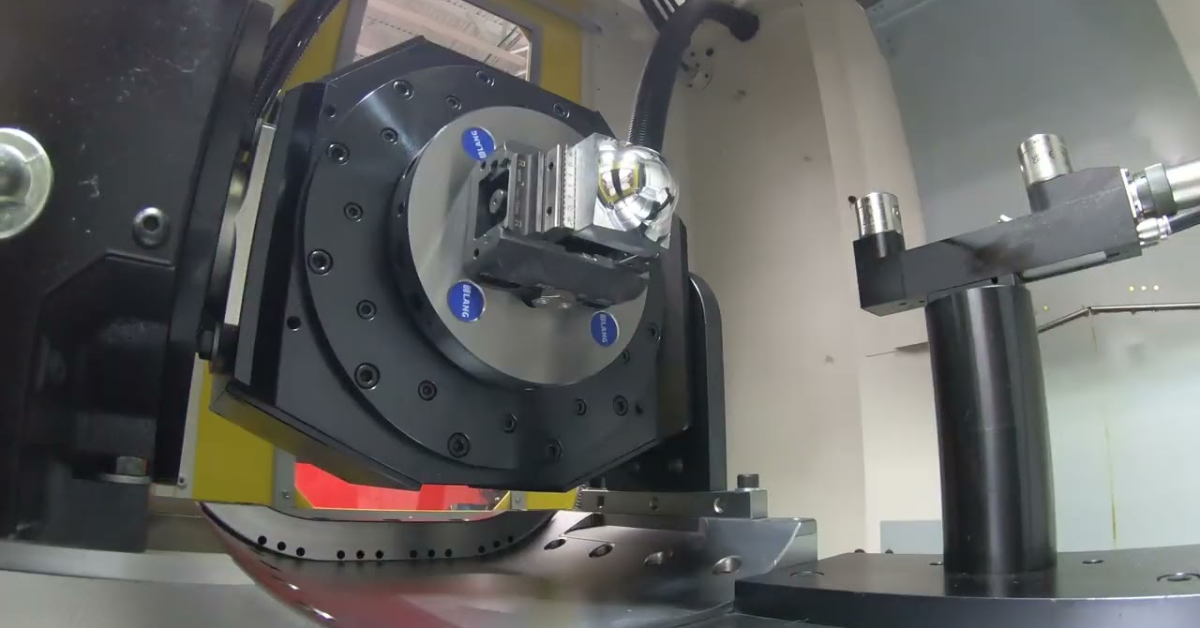

A Vertical Machining Center (VMC) is a CNC machine tool with a vertical spindle. Engineers create these machines to machine parts that need high precision. This includes molds, aerospace components, and automotive parts. VMCs excel in cutting. They provide precision, efficiency, and versatility.

The CNC double column vertical machining center is a special type of VMC. It’s known for its strength and heavy-duty use. Many industries rely on it for precision and high production rates. These machines have two vertical columns. They hold the workpiece and make it more stable during machining. This design helps the CNC double column VMC manage larger and heavier workpieces. It’s perfect for industries such as aerospace, automotive, and heavy machinery.

When picking a VMC, consider these factors: size, rigidity, precision, and speed. To pick the right machine for your production, start by knowing your needs. Then, consider your budget and production volume.

Key Factors to Consider When Choosing a VMC

Size of the workpiece:

The first factor to consider is the size of the parts you plan to machine. Choose a CNC double-column vertical machining center for large or complex workpieces. These machines are capable of handling larger workpieces with increased stability and precision. A double-column design can hold wide, heavy materials. This makes it great for industries that work with large components.

If your production includes small parts, a standard VMC might work. But a double-column machine gives you more flexibility as your operations grow.

Precision and Tolerances:

Precision is a vital factor in machining operations. The ability of a VMC to maintain tight tolerances has a direct impact on the quality of your parts. A CNC double-column vertical machining center provides great rigidity and stability. This leads to improved precision, especially with tough materials or complex designs. Machines that cut deflection are crucial in aerospace and medical device manufacturing. They lead to more accurate cuts, which are essential for high precision. This improves production quality and reliability.

Speed and Efficiency:

The speed of machining is another important factor that influences production efficiency. A high-speed VMC boosts output significantly, cutting down production time. Spindle speed, tool change time, and feed rate affect how fast a VMC finishes its tasks.

Manufacturers wanting to boost throughput can benefit from a VMC. A machine with faster cycle times and better tool management features is key. BORUI CNC machines have high-speed spindles and efficient tool changers. This setup cuts downtime and boosts machining productivity.

Automation and Control Features:

Automation tools such as automatic tool changers, robotic arms, and better CNC controls boost machining efficiency. Modern VMCs have advanced controls. These controls offer more programming flexibility. Some VMCs even support 5-axis machining, which allows for complex shapes.

A CNC double-column vertical machining center has high-tech controls. This lets you control multiple axes at the same time with great precision. This can change the game for shops. They can make complex parts without retooling or moving the workpiece many times.

Machine Maintenance and Support:

Vertical machining centers, like any high-precision equipment, need regular maintenance. This keeps them running smoothly. Pick a VMC from a trusted brand like BORUI CNC. This way, you’ll have dependable customer support and service when you need it. A maintenance plan is key. It helps avoid costly downtimes and keeps the machine running well.

Check for features that simplify maintenance. Look for accessible parts for routine checks and ensure spare parts are easy to find. A strong warranty and helpful after-sales support can reduce maintenance and repair risks.

What Makes BORUI CNC a Reliable Choice?

Choosing the right brand for a VMC is as crucial as picking the right specs. BORUI CNC is a top manufacturer in the industry. They focus on providing high-quality, reliable machines for many sectors. The VMC1160 is a 5-axis CNC vertical machining center. It excels at making versatile, high-performance machines. It meets the varied needs of today’s manufacturing industry.

BORUI CNC machines are built for precision, efficiency, and durability. They give users the flexibility to handle complex machining tasks. BORUI has solutions for everyone. We have the perfect machine for you. It doesn’t matter if you need high-volume production or detailed designs.

Conclusion:

To choose the best vertical machining center, you need to know your needs. Think about size, precision, speed, and budget. The CNC double-column vertical machining center is very stable. It can also manage large and heavy workpieces. This makes it perfect for industries that need high precision and strength.

Investing in a BORUI CNC vertical machining center offers reliable performance and modern technology. Plus, it offers solid support. This makes it a reliable choice for all machining operations. Picking the right VMC is key when you upgrade your setup or start a new production line. It helps you stay competitive and get the best results in manufacturing.

Stay in touch to get more updates & alerts on VyvyManga! Thank you