Revolutionizing Automobile Parts Inspection with AI-Powered Machine Vision Systems

In the rapidly evolving automotive industry, precision and efficiency are paramount, especially in the realm of automobile parts inspection. Traditional manual inspection methods are increasingly being supplanted by advanced technologies such as Automated Optical Inspection (AOI) systems and machine vision systems. These innovations are revolutionizing the way manufacturers ensure quality and accuracy in automobile parts production.

Challenges in Traditional Automobile Parts Inspection

Manual inspection of automobile parts presents several challenges:

- Human Error: Inspectors may overlook defects due to fatigue or oversight, leading to inconsistent quality assurance.

- Time-Consuming Processes: Manual inspections are labor-intensive and slow, potentially causing bottlenecks in production lines.

- Complexity in Detecting Subtle Defects: Minute flaws or internal defects are often challenging to identify without specialized equipment.

Advancements in AOI Systems and Machine Vision Technology

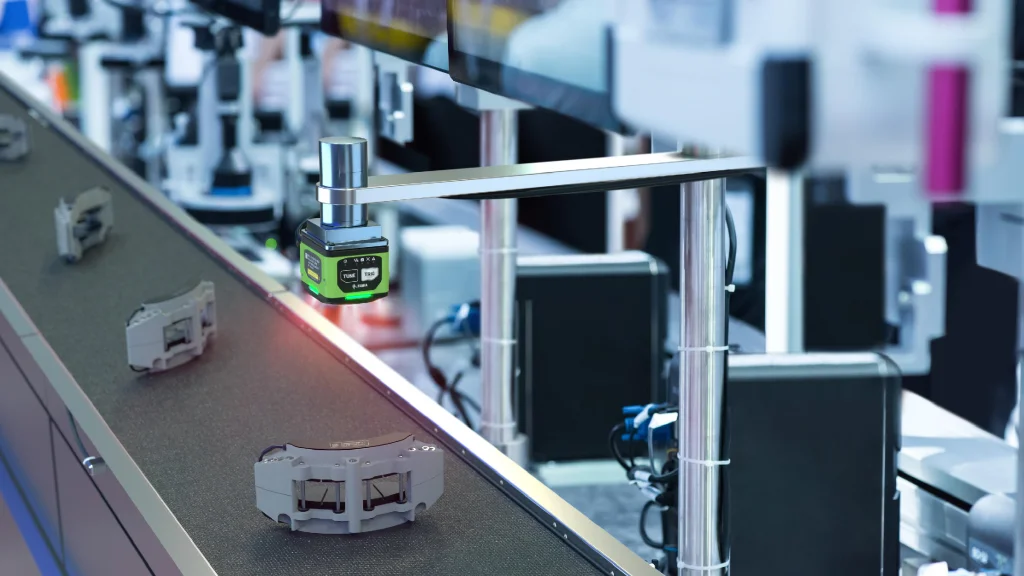

The integration of AOI systems and machine vision system addresses these challenges by automating the inspection process:

- High-Resolution Imaging: Advanced cameras capture detailed images, enabling the detection of minute defects that might be missed by the human eye.

- Consistency and Accuracy: Automated systems apply uniform inspection criteria, reducing variability and enhancing reliability.

- Real-Time Processing: Machine vision systems analyze images instantaneously, facilitating immediate identification and correction of defects.

Applications in the Automotive Industry

The adoption of AOI and machine vision systems has led to significant improvements in various inspection processes:

- Surface Defect Detection: Systems can identify scratches, dents, and other surface imperfections on metal sheets and components.

- Dimensional Accuracy Verification: Machine vision systems measure parts to ensure they meet precise specifications, crucial for components like engine parts and safety mechanisms.

- Assembly Verification: AOI systems confirm the correct assembly of components, ensuring that all parts are present and properly aligned.

Case Study: Integic’s AI-Driven Inspection

A notable example of AI-driven inspection technology is Intelgic’’s Vision AI system, which utilizes computer vision to scan vehicles and detect issues within seconds. The system scans vehicles rapidly, providing comprehensive condition reports that enhance the efficiency and accuracy of inspections.

Benefits of Implementing AOI and Machine Vision Systems

The integration of these technologies offers numerous advantages:

- Enhanced Quality Control: Automated systems ensure that all parts meet stringent quality standards, reducing the likelihood of defects reaching consumers.

- Increased Efficiency: Automation accelerates the inspection process, allowing for higher production rates without compromising quality.

- Cost Reduction: By minimizing manual labor and reducing the incidence of defective products, manufacturers can achieve significant cost savings.

Future Trends

The continuous advancement of AI and imaging technologies is expected to further transform automobile parts inspection:

- Integration with IoT: Combining machine vision systems with the Internet of Things (IoT) can enable real-time monitoring and data analysis across production facilities.

- Predictive Maintenance: AI algorithms can predict equipment failures before they occur, allowing for proactive maintenance and reducing downtime.

- Enhanced Data Analytics: Advanced data processing can provide deeper insights into production processes, facilitating continuous improvement and innovation.

The adoption of AOI systems and machine vision technology is revolutionizing automobile parts inspection, offering unprecedented levels of accuracy, efficiency, and reliability. As these technologies continue to evolve, they will play an increasingly critical role in ensuring the quality and safety of automotive components, thereby enhancing overall industry standards and consumer satisfaction.