Key Challenges Solved by Bifilar and Trifilar Coil Winding Explained

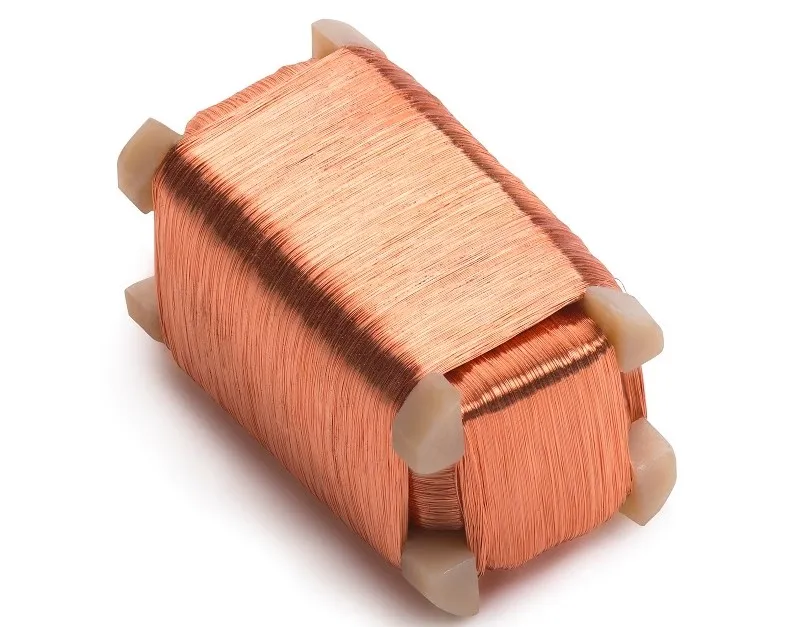

The need for accurate microcomponents is increasing today as technology gets smaller and smaller. Coil winding is a major player in this area, especially bifilar and trifilar coil winding. These coils are necessary for many tasks, from sending signals to storing energy. However, making them isn’t easy, especially since gadgets keep getting smaller. Let’s examine how bifilar and trifilar coil windings resolve some problems.

Overcoming Design Challenges in Micro-Coil Production

Engineers are in charge of making micro coils that meet strict requirements as modern equipment gets smaller. This is not an easy task. There are clear benefits to using bifilar and trifilar coils, which have two and three conductors, respectively, when currents need to run in parallel or opposite directions. But these coils have problems, like making sure they keep working well despite being small. These are the times when bifilar and trifilar twisting are proper.

A Lot of Production

People want these tiny coils not only for accuracy but also for mass production. Economical mass production is very important, especially for fields that need many of these parts. Bifilar and trifilar winding technologies help solve this problem by allowing consistent output with high yields and little waste, which makes the process reliable and cost-effective.

Tightness and Dependability

One of the most complex parts of making micro coils is getting the specs very close. Even a minor difference can cause something wrong when working with excellent lines. Bifilar and trifilar coil windings must meet these strict standards to work reliably over time. Also, problems like oxidation and poor conductivity don’t happen, which can occur with standard soldering methods.

Preventing Manufacturing Damage

When coils get smaller, there is a greater chance of damaging fragile insulation or windings. This problem occurs frequently when making micro-coils because the wrapping process must be done carefully. Automatic, state-of-the-art winding technologies wind coils without damaging the fine wire or insulation, which can happen when doing it by hand.

Ensure Longevity and Durability

Longevity is essential for any part, but especially for technology. Bifilar and trifilar coils often have trouble staying strong in harsh situations. Using advanced thermo-pressure bonding technology and precise engineering, they can solder fine wires together without the usual problems of oxidation and bad conductivity. This makes the parts more reliable and last longer.

Why Should You Pick Bifilar and Trifilar Coils?

Bifilar and trifilar coils are necessary for tasks requiring complicated current flows. They also have significant advantages over regular wire-wound resistors. They work exceptionally well for projects like Ethernet cables and power sources that need to eliminate harmful magnetic effects. Every company uses advanced manufacturing techniques to ensure that these coils are high quality. They are a reliable and cost-effective option.

Conclusion

Bifilar and trifilar coil winding help engineers and makers deal with many problems when making smaller parts that work better. These coils are essential in high-performance uses because they help keep tolerances tight and ensure the parts last a long time. With cutting-edge tools like thermo-pressure bonding, the difficulties of making micro-coils are no longer problems but steps towards a better, more dependable future.