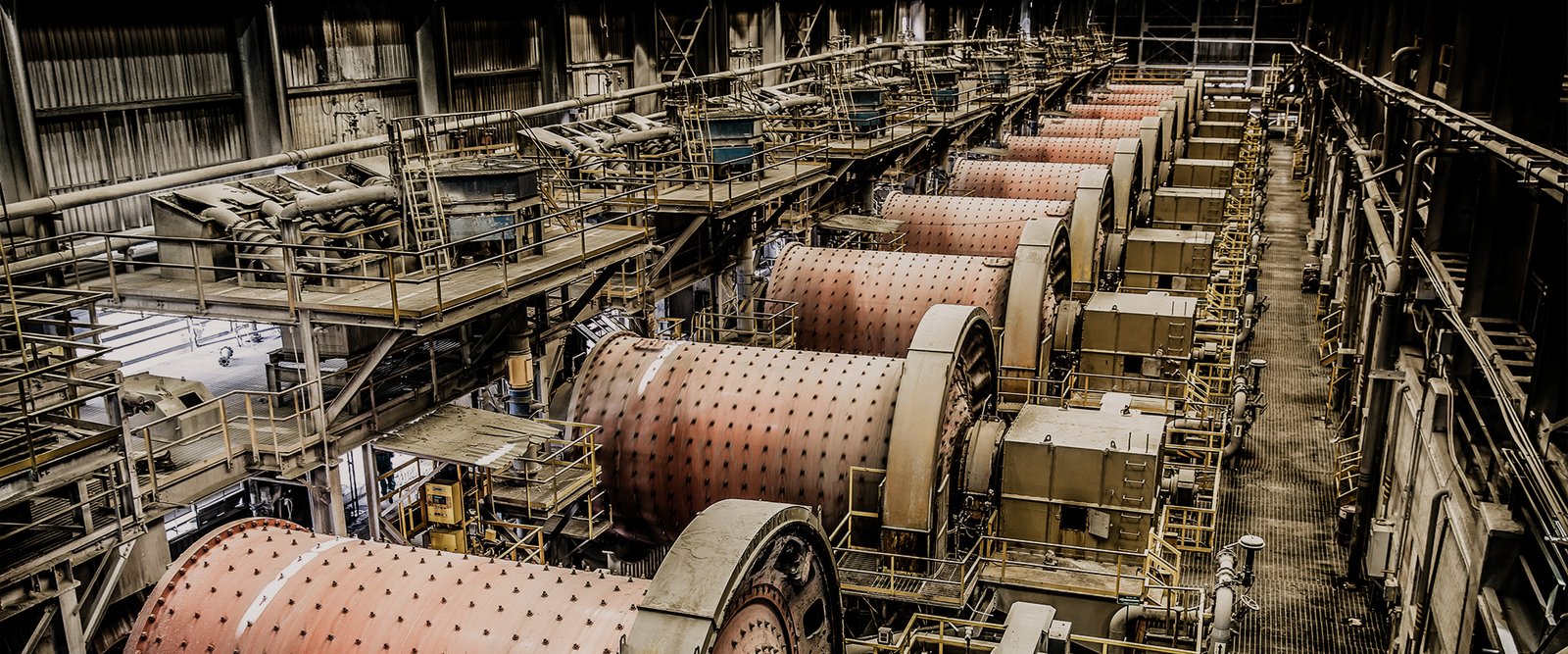

Revolutionizing Production with Mineral Processing Equipment

Industrial success increasingly depends on the use of advanced mineral processing equipment. These systems play a vital role in ensuring that raw materials are refined to meet strict specifications before being transformed into finished products. The quality of these materials directly impacts the performance and durability of the final products, making accuracy and consistency critical in every phase of processing.

From precision crushers to dynamic classifiers and filtration systems, modern processing equipment maximizes throughput while minimizing environmental impact. This makes it possible to maintain profitability while operating responsibly. These machines are now equipped with automated controls and real-time monitoring features, allowing for smarter decision-making and early fault detection.

KSE: Engineering Tomorrow’s Industrial Solutions

KSE is a global innovator in automation and process technology, serving critical industries such as feed, food, and minerals. With decades of experience, KSE has earned a strong reputation for delivering advanced solutions that simplify complex production processes. Their integrated approach combining cutting-edge hardware, intelligent software, and deep industry-specific knowledge allows them to create systems that are both scalable and flexible, adapting easily to changing demands and market conditions.

A Reputation Built on Precision and Trust

KSE’s success is rooted in three core principles: precision, reliability, and innovation. Their equipment is engineered for accuracy and long-term performance, ensuring that every batch, blend, or process meets exact standards. This level of consistency is essential in industries where quality and safety are non-negotiable. Clients rely on KSE not only for their high-performance machinery but also for their consultative approach and long-term support.

Driving Sustainable and Future-Proof Solutions

In an era where sustainability is a global priority, KSE’s technology helps companies meet environmental and operational goals. Energy-efficient systems, reduced material waste, and automation that lowers human error contribute to greener production lines. With real-time monitoring and predictive maintenance features, downtime is minimized and resource usage is optimized.

By investing in KSE’s forward-thinking solutions, companies are not just enhancing today’s efficiency, they are aligning with future-proof strategies that support long-term growth, environmental responsibility, and competitive advantage in a rapidly evolving industrial landscape.

Future Sustainability Begins with Smart Technology

In today’s fast-evolving industrial landscape, sustainability is more than a trend it is a necessity. The shift toward greener operations is being powered by smart technology, which plays a vital role in making processes cleaner, more efficient, and more responsible. From energy management to predictive maintenance, intelligent systems are at the core of the transformation.

Intelligent Systems for Efficient Operations

Smart technology allows industries to monitor and control operations with unprecedented precision. Sensors collect real-time data, allowing for accurate tracking of energy use, emissions, and resource consumption. This data is then analyzed using AI-driven platforms to identify inefficiencies and suggest improvements. As a result, waste is reduced, energy usage is optimized, and production costs are significantly lowered all while maintaining high output quality.

Enabling Predictive and Preventive Approaches

One of the key advantages of smart systems is the ability to predict issues before they occur. Equipment health can be monitored continuously, enabling preventive maintenance rather than reactive repairs. This reduces downtime, extends equipment lifespan, and minimizes unnecessary material loss.

Aligning with Global Environmental Goals

By adopting smart technologies, industries align themselves with global sustainability targets. Lower emissions, reduced water use, and responsible waste handling contribute to a smaller environmental footprint. These improvements not only meet regulatory requirements but also enhance brand reputation and investor confidence.

Conclusion

The integration of advanced mineral processing equipment and smart technology is revolutionizing industrial production. Companies like KSE are at the forefront, offering scalable, efficient, and sustainable solutions tailored to the demands of modern industries. By embracing automation, real-time monitoring, and precision engineering, businesses can enhance productivity while reducing their environmental impact. These innovations not only improve operational performance but also align with long-term goals for sustainable development. As global demands continue to evolve, the industries that adopt intelligent, future-proof technologies will lead the way.