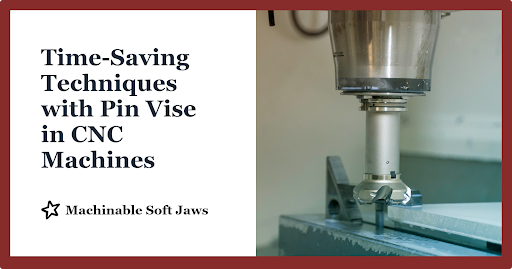

Time-Saving Techniques with Pin Vise in CNC Machines

In the field of CNC machining, being efficient is essential. A standout tool for boosting productivity is the PinVise. It’s excellent for securely holding small items making it a crucial asset for CNC experts. This article will look at time-saving methods using this tool emphasizing its benefits and uses in CNC machines.

Essential Facts About PinVise

A Pin Vise is a straightforward yet adaptable tool mainly used to keep small parts in place firmly. It’s crafted to manage tiny objects making it perfect for detailed machining jobs. The tool’s extremely low-profile design and light build make it a top pick for use with tombstones and automation systems. Its compatibility with RockLock and the option to direct mount from above with SHCS and dowels further improve its practicality in CNC machining.

PinVise – Key Advantages Explained

Precision and Control

If precision is your priority in CNC work, then choosing a 5th Axis Pin Vise will help you achieve the best results with ease. It offers outstanding precision and control which are vital for detailed CNC tasks. Its design ensures a tight grip on small parts reducing the risk of slippage or misalignment. This accuracy is especially valuable when handling delicate parts, ensuring precision and lessening the need for redoing work.

Time-Saving

A major benefit of using a Pin Vise in CNC machines is the time it saves. The tool’s ability to securely hold parts means fewer stops during the machining processes. This efficiency leads to quicker completion of projects allowing CNC professionals to handle more tasks and boost productivity.

Versatility

The Pin-Vise is incredibly flexible. It can be employed in various tasks from holding tiny screws and pins to managing delicate parts needing detailed machining. This flexibility makes it a valuable addition to any CNC workshop offering solutions for many tasks.

Lightweight and Durable

Despite its light design the PinVise is tough and sturdy. It’s made from high-quality materials that endure daily use in a CNC setting. This sturdiness ensures that the tool lasts providing dependable performance over time.

Applications of Soft Jaw Pin Vise in CNC Machining

Holding Small Parts

A primary function of this tool is to keep small parts securely during machining. This use is especially helpful when dealing with components too small to be clamped using standard methods. By securing these parts well it ensures they stay in place during the machining process.

Fine Detail Work

For CNC experts focused on projects needing fine detail the Pin Vise is crucial. Its ability to keep parts steady allows for detailed cuts and precise detailing improving the quality of the final product. This feature is particularly important in industries where detail is critical.

Prototyping and Small-Scale Production

In prototyping and small-scale production the PinVise proves invaluable. It allows for quick setup and adjustments letting CNC professionals try different designs and iterations without significant downtime. This adaptability is key for innovation and effective production processes.

Tips for Maximizing the Use of Pin Vise

Proper Selection of Jaws

Selecting the appropriate jaws for your Pin-Vise is crucial for its full effectiveness. Steel machinable soft jaws (S) are advised for their firm grip on parts without causing damage. These jaws can be tailored to match specific components ensuring a perfect hold and top performance.

Regular Maintenance

To maintain the longevity and effectiveness of your Vise, regular upkeep is necessary. Keep the tool clean and clear of debris and check for any signs of wear or damage. Consistent maintenance will ensure it continues to work well providing reliable outcomes.

Integration with Automation Systems

The light and low-profile design of the vise makes it ideal for integration with automation systems. By incorporating the Pin Vise into automated workflows CNC professionals can further boost efficiency and productivity. This integration permits continuous operation reducing manual handling and increasing output.

Last Words

The PinVise is a crucial tool for CNC professionals offering numerous benefits that enhance productivity and efficiency. Its precision versatility and durability make it suitable for a wide range of applications from holding small parts to fine detail work. By using time-saving methods with the Pin-Vise CNC professionals can streamline their workflows, reduce downtime and achieve superior results. Embrace the capabilities of the Pin Vise and take your CNC machining to new heights.

Stay in touch to get more updates & alerts on VyvyManga! Thank you