What Makes John Emmert’s FDA Reports Unique: A Pattern Analysis

FDA John Emmert has built a reputation for audits that go beyond the standard checklist. His inspection reports consistently reveal deeper, system-wide vulnerabilities especially in areas where documentation fails to reflect actual practices. Whether it’s data integrity, inadequate investigations, or lapses in process validation, Emmert’s observations often expose gaps that suggest a breakdown in both compliance culture and operational oversight.

In this article, we’ll examine what sets Emmert’s reports apart, explore recurring patterns across his inspections, and explore how manufacturers can use these insights to identify hidden risks and strengthen their GMP readiness before the FDA steps in.

Who is John E. Emmert?

John E. Emmert is a seasoned FDA Investigator with extensive experience conducting inspections for a variety of industries, primarily focusing on food and health-related manufacturing.

As a Consumer Safety Officer, Emmert plays a key role in evaluating the compliance of manufacturers with Good Manufacturing Practices (GMP) and other FDA regulations. His work is instrumental in helping companies maintain compliance with the FDA, minimize risks, and ensure public health safety.

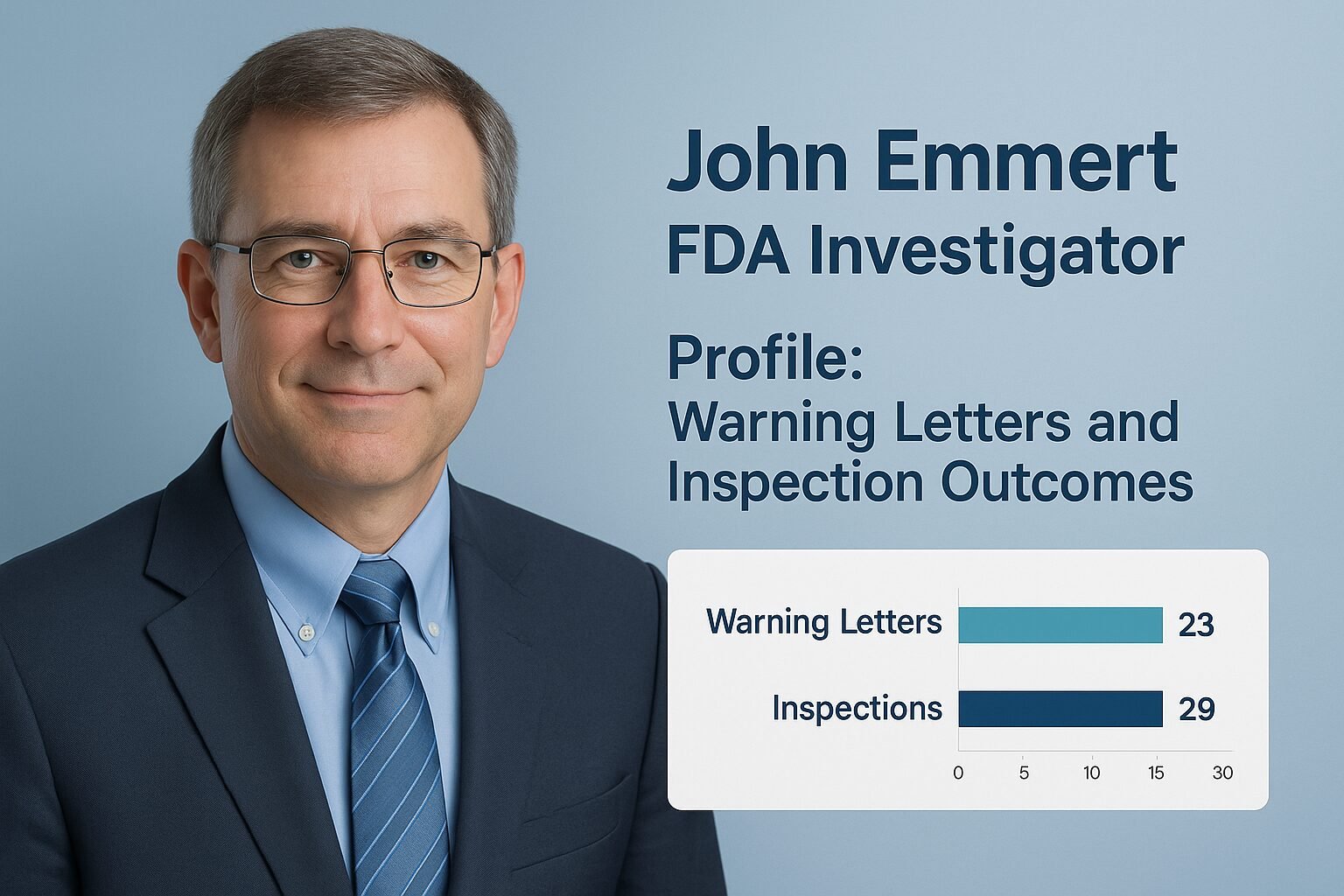

Key Stats on John E. Emmert’s Inspections:

- Total Inspections: 630

- Total 483s Issued: 35

- Total Warning Letters Issued: 0

- Longest Inspection: 38 days

- Shortest Inspection: 1 day

- Average Length of Inspection: 0.9 days

Key Areas FDA Inspectors Focus on During Inspections

FDA inspectors like John E. Emmert examine several critical areas to ensure that products meet safety and regulatory standards. Here are some of the most common focus points during FDA inspections:

- Sanitation and Hygiene Practices: Inspectors assess whether facilities are following proper sanitation protocols to prevent contamination in food, pharmaceutical, and medical device manufacturing.

- Product Safety and Handling: Ensuring that products are stored, transported, and handled correctly is crucial for compliance. Inspectors look for any potential risks to product safety.

- Documentation and Record Keeping: Accurate and complete documentation of production and quality control processes is essential. Inspectors verify whether companies maintain records in line with FDA standards.

- Quality Control Measures: Inspectors often review the effectiveness of a company’s quality control system to ensure products meet safety standards before reaching the market.

- Labeling and Packaging Compliance: Mislabeling or inadequate packaging is a frequent concern during inspections, and inspectors ensure that products are accurately labeled as per FDA guidelines.

Key Observations from John E. Emmert’s Inspections

Emmert’s inspections provide important insights into recurring compliance issues that manufacturers must address. While Form 483s are common, he has not issued any warning letters, indicating that his inspections primarily highlight areas for improvement rather than immediate legal actions. Below are some of the main observations based on his inspection reports:

- Failure to Comply with GMP (Good Manufacturing Practices)

One of the most common issues identified during Emmert’s inspections is the failure to adhere to Good Manufacturing Practices (GMP). GMP violations can include improper sanitation, inadequate equipment maintenance, or a lack of proper documentation for production processes. These issues can lead to contamination, product quality problems, and, ultimately, regulatory non-compliance.

Best Practice: Manufacturers should conduct regular audits of their processes to ensure strict adherence to GMP, including maintaining clean facilities, ensuring proper employee training, and documenting all procedures accurately.

- Inconsistent or Incomplete Documentation

In Emmert’s inspections, inconsistent or incomplete documentation of production processes often emerges as a recurring issue. Proper documentation is vital to track production, testing, and quality control processes, ensuring that the company is meeting FDA standards. Inadequate record-keeping or failure to retain relevant documentation can result in inspection failures.

Best Practice: Manufacturers should implement thorough documentation procedures, ensuring that every stage of production is recorded accurately and can be easily accessed in case of an inspection.

- Quality Control Failures

Quality control (QC) is another common area where Emmert’s inspections reveal deficiencies. These include issues such as failing to adequately test products, using substandard materials, or failing to detect product defects before they reach the market. QC failures can lead to serious health risks, especially in the food and medical device industries.

Best Practice: Implement a robust QC system that includes routine product testing, proper equipment calibration, and immediate corrective actions for any detected deficiencies.

- Inadequate Adverse Event Reporting

In some inspections, Emmert has found that companies fail to report adverse events as required. Timely reporting of adverse events, such as defects or consumer complaints, is critical to ensure that products are safe and that consumers are not put at risk.

Best Practice: Ensure that your company has a system in place to monitor and report any adverse events quickly and accurately to the relevant authorities.

- Improper Labeling and Packaging

Emmert’s inspections have also highlighted labeling and packaging issues, such as mislabeling of ingredients, improper storage conditions, or misleading claims about product efficacy. These violations can lead to legal actions and tarnish a company’s reputation.

Best Practice: Ensure that all labels and packaging meet FDA guidelines, with accurate information about ingredients, usage instructions, and potential risks.

Recent Inspections Conducted by John E. Emmert

Some notable inspections conducted by John E. Emmert include:

- 2021-11-29: Global Sterilization and Fumigation (Sioux Falls, United States)

- 2021-11-23: United Ground Express (Sioux Falls, United States)

- 2021-11-05: Hearthside Food Solutions, LLC (North Sioux City, United States)

- 2021-10-21: Walt’s Homestyle Foods, Inc. (Yankton, United States)

- 2021-10-15: Bizzy Lizzy Bakery (White, United States)

These recent inspections show a focus on food production and service companies, which highlights the ongoing importance of food safety and proper sanitation in manufacturing processes.

Unique Patterns in John E. Emmert’s FDA Findings

While many FDA investigators follow a consistent structure during inspections, John E. Emmert’s reports reveal distinct patterns that set his audits apart. His observations consistently reflect a preference for evidence-based evaluation, with a focus on the practical execution of compliance, not just documented intent.

Here are some notable patterns that stand out across Emmert’s inspections:

1. Strong Emphasis on Documentation That Matches Practice

Unlike inspectors who may accept neatly filed SOPs at face value, Emmert often cross-verifies whether procedures are actually followed on the floor. If records indicate sanitization was performed daily, he’ll ask employees to demonstrate that process or request time-stamped logs and cleaning schedules. When there’s a disconnect between what’s written and what’s done, it’s flagged immediately.

Pattern Insight: Emmert’s inspections challenge companies to prove that documentation isn’t just created for the audit it reflects actual operations.

2. Frequent Citations Related to Overlooked Daily Controls

Emmert tends to catch compliance gaps in routine operations like missing daily hygiene checks, outdated batch records, or unlabeled raw materials in staging areas. These might seem like minor lapses, but in Emmert’s reports, they point to broader weaknesses in supervision and GMP culture.

Pattern Insight: Emmert identifies small details that suggest systemic issues, particularly around daily accountability.

3. Focus on Sanitation as a Compliance Barometer

Emmert often uses sanitation practices as a bellwether for overall GMP compliance. He inspects floor drains, cleaning tools, sanitation logs, and even employee hygiene facilities. In food and drug environments, lapses in this area are treated seriously—even if they haven’t yet resulted in contamination.

Pattern Insight: If sanitation is weak, Emmert often assumes other GMP areas may be similarly neglected.

4. Education-Oriented Reporting Style

Although he identifies clear compliance issues, Emmert’s reports typically lack the adversarial tone found in some 483s. Instead, his observations tend to be instructive—flagging gaps while implicitly guiding firms on how to improve. This may explain why his inspection history includes zero warning letters, despite dozens of 483s.

Pattern Insight: Emmert’s findings offer a chance for corrective action—not regulatory escalation—if manufacturers take them seriously.

5. Recurrent Issues in Adverse Event Reporting

Across several inspections, Emmert has highlighted underdeveloped systems for reporting adverse events or consumer complaints. Whether due to poor training or unclear SOPs, failure to report such events can result in compliance citations—even if no actual harm occurred.

Pattern Insight: Emmert treats complaint handling as a reflection of a company’s commitment to public health responsiveness.

By recognizing these unique patterns, manufacturers can prepare more strategically for a John E. Emmert inspection. His focus on real-world execution, day-to-day controls, and public safety makes his audits both challenging and highly valuable for long-term compliance improvement.

How Manufacturers Can Benefit from Emmert’s Reports

- Proactive Compliance: By reviewing Emmert’s inspection reports, companies can identify potential weaknesses in their processes and address them before a formal inspection occurs.

- Benchmarking and Best Practices: Emmert’s reports serve as a benchmark for FDA expectations, allowing manufacturers to align their practices with the best in the industry.

- Risk Mitigation: Identifying common compliance issues in Emmert’s inspections allows businesses to mitigate future risks and stay ahead of regulatory requirements.

Conclusion

John E. Emmert’s inspections provide invaluable insights into recurring compliance issues in regulated industries like food, pharmaceuticals, and medical devices. By understanding his observations, like GMP adherence, documentation practices, and labeling requirements, companies can stay proactive and better prepared for FDA inspections.

Companies seeking to gain a deeper understanding of FDA inspection data and trends can find support from leading intelligence organizations like Atlas Compliance. They offer insights into inspection patterns and help manufacturers streamline their compliance efforts, ensuring smoother and more predictable FDA inspections.