How to Get Custom Laser Cutting Solutions in Melbourne for Precise Results

Manufacturing precision components, architectural elements, and specialized design pieces requires fabrication technologies that deliver exceptional accuracy while accommodating complex geometries. Custom laser cutting solutions in Melbourne represent the intersection of advanced industrial capability and accessible manufacturing services for projects demanding precise tolerances, clean edges, and repeatable results. The city’s manufacturing landscape includes diverse service providers ranging from boutique design-oriented fabricators to industrial-scale production facilities equipped with multi-kilowatt fiber, CO2, and ultraviolet laser systems. This technological diversity enables remarkable material versatility and geometric complexity previously unattainable through conventional fabrication methods. Understanding the technical specifications, material considerations, and production workflow optimizations ensures your custom laser cutting projects achieve optimal precision while maximizing cost-effectiveness.

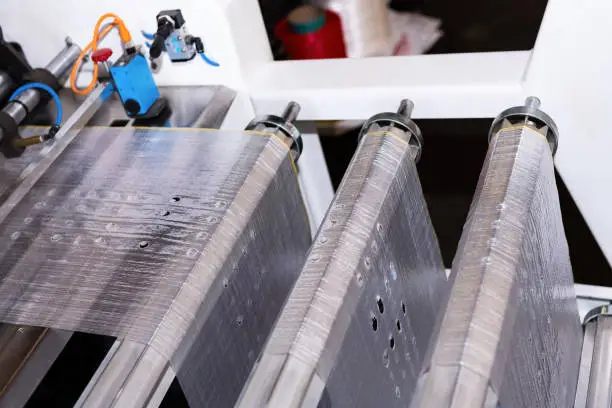

Understanding Laser Cutting Technology Variations

Melbourne’s laser cutting landscape encompasses several distinct technologies, each offering specific advantages for particular applications. CO2 lasers (typically 30- 400W for precision work) excel at processing organic materials, including wood, paper, leather, and acrylic, while handling thinner metals effectively. These systems achieve kerf widths of 0.08-0.2mm depending on material properties. Fiber lasers (500W-6kW) deliver superior performance on reflective metals, including aluminum, copper, and brass, with exceptional edge quality and narrower kerf widths averaging 0.05-0.1mm. Newer ultraviolet laser systems offer micromachining capabilities for specialized applications requiring tolerances below 0.025mm. Understanding these technological distinctions helps match your project requirements with appropriate service providers. Melbourne’s industrial area,s including Dandenong, Bayswater, and Campbellfield, hosts higher-power systems optimized for thicker materials, while inner-city fabricators typically operate lower-power systems focused on design applications requiring finer detail in thinner stock.

Material Selection and Specification Optimization

Achieving optimal results requires careful material selection and specification development before approaching fabricators. Material thickness significantly impacts both pricing and quality outcomes—standard sheet thicknesses aligned with common manufacturing specifications typically yield cost advantages of 15-30% compared to custom gauges. Material certification requirements should be established before fabrication, particularly for structural applications. Melbourne suppliers can typically provide mill certifications for metals and compliance documentation for specialized materials like fire-rated acrylics or food-safe polymers when requested before processing. Surface coating considerations require special attention—powder-coated metals often require edge treatment after cutting to prevent corrosion at heat-affected zones, while anodized aluminum may exhibit color changes within approximately 0.5mm of cut edges. For precision applications, material flatness specifications should be explicitly communicated, as standard commercial tolerances may prove insufficient for fine-tolerance assemblies.

File Preparation and Technical Documentation

Fabrication accuracy depends significantly on proper file preparation and comprehensive technical documentation. Vector files in .dxf, .dwg, or .ai formats with precisely defined cutting paths yield optimal results compared to raster-based formats requiring conversion. Line weights should be standardized at 0.01mm to clearly differentiate cutting paths from dimension lines or annotations. Explicit tolerance specifications prevent misinterpretations—Melbourne fabricators typically work to ±0.1mm as standard tolerance unless otherwise specified. Nesting efficiency significantly impacts pricing for multiple-unit productions; providing complete assemblies rather than individual components allows fabricators to optimize material utilization. For complex projects, supplementary documentation should include material specifications, required edge quality (Ra value), and any post-processing requirements such as deburring, countersinking, or tapping. Melbourne’s specialized fabricators can typically accommodate GD&T (Geometric Dimensioning and Tolerancing) documentation for precision components when provided in standard ASME Y14.5 format.

Production Process Considerations and Quality Assurance

Establishing appropriate quality assurance protocols ensures fabrication outcomes meet project requirements. For precision applications, request specific metrology methodologies—Melbourne’s advanced fabricators utilize coordinate measuring machines (CMMs), achieving accuracy to ±0.005mm for critical dimensions, while standard inspection typically employs digital calipers with ±0.02mm accuracy. Edge quality requirements should be explicitly defined using Ra values rather than subjective descriptions. First-article inspection protocols prove particularly valuable for production runs exceeding 10 identical components, allowing verification before full production commitment. Lead time considerations vary significantly across Melbourne’s fabrication landscape—boutique fabricators typically operate on 5-10 day schedules for standard projects, while high-volume industrial providers may require 2-3 weeks for production scheduling but offer expedited services at premium rates. Understanding these production workflows enables realistic project planning while avoiding unnecessary expediting costs.

Specialized Applications and Advanced Capabilities

Melbourne hosts several fabricators offering specialized capabilities beyond standard cutting operations. Tube and pipe cutting systems accommodate three-dimensional fabrication for architectural and structural applications, processing round stock from 10-300mm diameter with rotational accuracy of ±0.2 degrees. Combined laser-punch systems enable secondary operations including countersinking, dimpling, and forming within the same production cycle, reducing handling requirements and improving dimensional accuracy between features. Photographic engraving capabilities leverage raster processing to create detailed surface imagery with 256 gray levels at resolutions up to 1200dpi on compatible materials. For development projects, several Melbourne fabricators offer integrated design consulting services where experienced technicians provide manufacturing-oriented design refinements to improve producibility while maintaining functional requirements. These specialized capabilities enable complex fabrication outcomes exceeding conventional manufacturing approaches in both quality and cost-effectiveness.

Stay in touch to get more updates & alerts on VyvyManga! Thank you