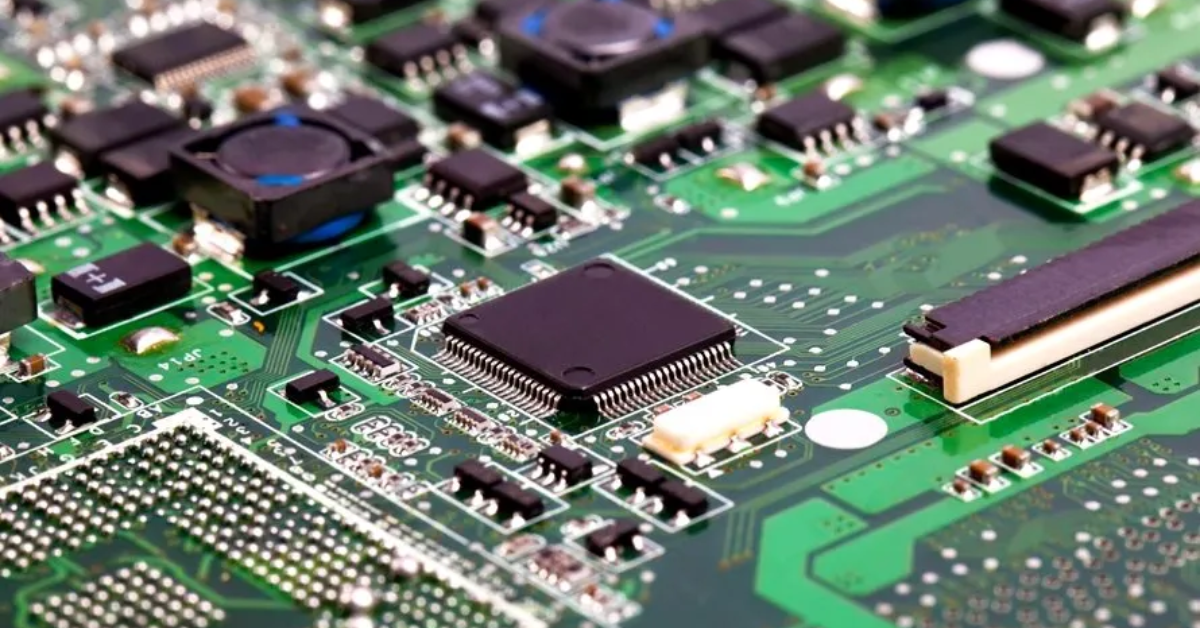

Understanding PCB Thickness: A Key Design Parameter

The thickness of the PCB is one of the most important determinants of the design and operational capabilities of printed circuit boards. It changes the actual dimension of the board, the performance of the signals that it conveys, and compatibility with other components. Hence, the knowledge of thickness and its potential implications contributes to the production of sound PCB-based electronic devices. This article focuses on the identification of standard PCB thicknesses, measures that determine thickness, and the part played by thickness on performance.

What is PCB Thickness?

PCB thickness means how many layers the printed circuit board has, including all of them. A PCB consists of multiple layers:

- Substrate: The first layer, often known as the base material, is commonly fiberglass, or FR4.

- Copper: ELECTRICAL CONDUCTIVE PATHWAYS through which electrical signals should flow. Get more information by visiting the official website.

- Solder Mask: Prevents solder from utilizing the copper traces at its base by shielding the whole area to avoid short circuits.

- Silkscreen: Designates marks to show where the parts are assembled and where the various faults may occur.

The overall thickness of PCB is also designed by the thickness of each layer, and it can change according to the need of the design and utilization.

Standard PCB Thickness

The mean value is 1.57mm (0.062 inch) which can be regarded as standard and facilitates industry compatibility in manufacturing and usage of parts. Other typical thicknesses include:

0. Even thinner, at 8mm (0.031 inches) for compact devices or 9.9mm (0.391 inches) for large ones.

2.36mm (0.093 inches) for long-term, wide service use.

Optional thicknesses for specific applications include thin-gauged from 0.2mm up to above 3mm.

Identified Factors Affecting PCB Thickness

1. Number of Layers

Single-side boards are correspondingly thinner as compared to the multilayer boards used in sophisticated electronic products, which also have more layers and are thicker.

2. Material Type

The substrate is FR4, polyimide, or a metal core thickness is affected. Metal-core boards are more massive than conventional IT applications such as FR4 though they are used to enhance the thermal cooling requirements.

3. Copper Thickness

Relative to the previous type, the commonly used copper thickness is 1 oz/ft², which is equivalent to 0.0362 mm. But to handle higher currents, the thickness of copper foil may be greater, which leads to an overall increase in the thickness of the printed circuit board.

4. Application Requirements

Smartphones, for instance, require thinner boards, and more space is required; industrial applications, on the other hand, require thicker BOARDS more strength is needed.

5. Mechanical Stability

Thicker PCBs are more rigid in which applications are susceptible to vibrations or mechanical stressing force.

6. Thermal Management

The boards, as applied to high-temp applications, may need thicker base material or extra layers to enhance the dissipation of heat.

Importance of PCB Thickness

1. Durability

Thicker means more dense and mechanical strength in the substrate is good for mechanical stress applications like automotive, aerospace, and industrial.

2. Signal Integrity

The thickness of the PCB influences the impedance and different thicknesses will impact signal integrity in high-frequency circuits.

3. Thermal Performance

Wood that has thicker laminations or multiple laminates has better heat-expelling ability and is suitable for use in power applications.

4. Component Compatibility

Connectors and enclosures should also correspond to the thickness of the PCB, and thickness can significantly affect assembly.

5. Flexibility

Thin PCBs are employed in use where flexibility is needed such as in the construction of bend or fold mechanisms like in wearable gadgets.

Applications of PCB Thickness

- Consumer Electronics

- Automotive and Aerospace

- High-Frequency Applications

- Industrial Equipment

The importance of understanding the thickness of PCB as a parameter to measure and determine the level of customization.

The thickness of the printed circuit boards is measured physically during the manufacturing process employing the help of a calibrated caliper or any other kind of gauging tool. All dimensions are generally within 10% tolerance of the thickness that has been specified. Modern production techniques allow for highly customized thickness to meet specific needs, including:

- Electrical performance.

- Mechanical strength.

- Environmental conditions.

Conclusion

Thickness is one of the most basic parameters of circuit boards that impact the overall sturdiness, functionality, and compatibility of the boards. Normal thicknesses of 1.57mm thicknesses are commonly used occasionally; however, application thickness can be ever-changing to suit various vertical applications.

Stay in touch to get more updates & alerts on VyvyManga! Thank you