Boosting Motor Performance with Advanced BLDC Winding Machines

In recent times, advancements in motor technology have paved the way for more effective and important motors, particularly in diligence similar as automotive, robotics, and renewable energy. One of the crucial inventions driving these advancements is the development of the BLDC winding machine. The rise of brushless motors, particularly Brushless DC( BLDC) motors, has revolutionized colorful sectors due to their high effectiveness, long lifetime, and minimum conservation conditions. still, the performance of these motors depends significantly on the perfection and quality of the winding process, which is where the part of a motor winding machine automatic becomes pivotal.

The part of BLDC Winding Machines in Motor Performance

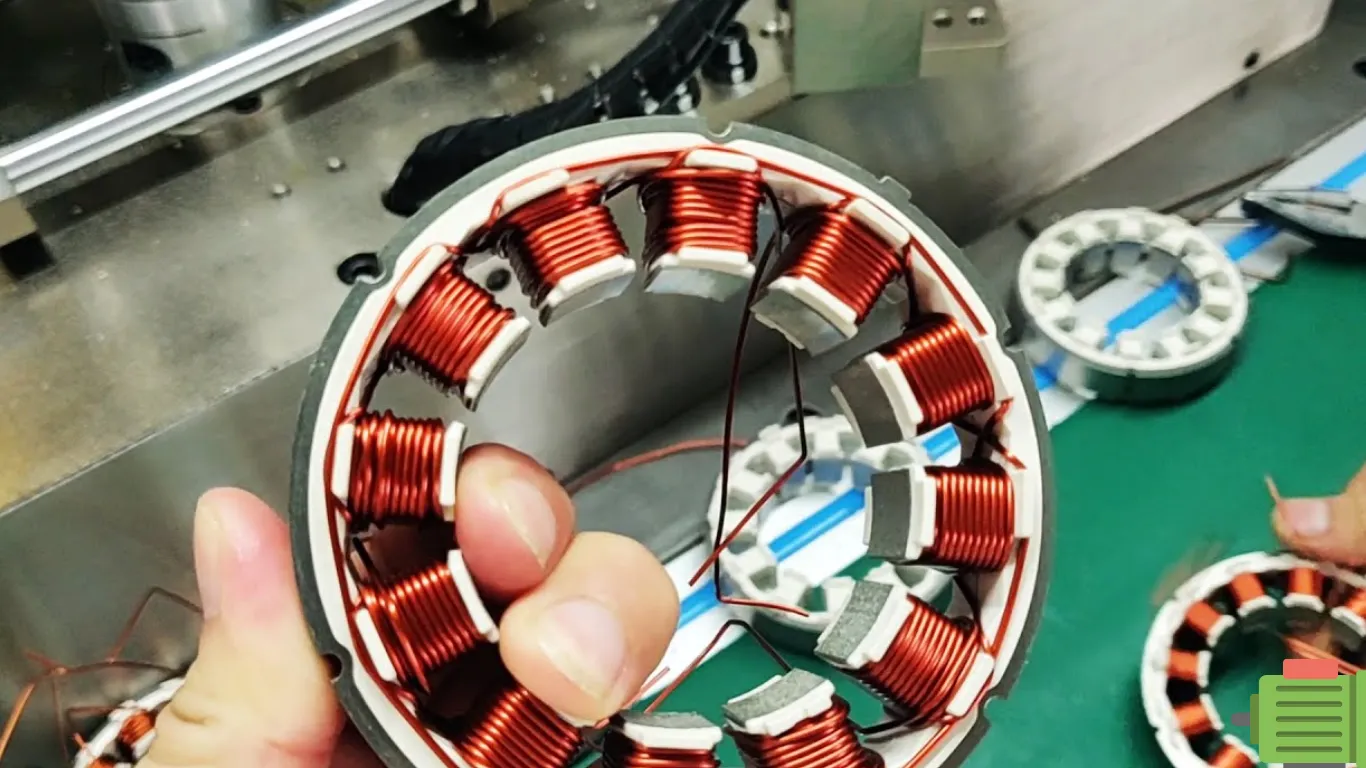

A BLDC winding machine is designed specifically to wind the coils for brushless DC motors. These motors are known for their trustability, effectiveness, and capability to operate without the need for a commutator, which is generally set up in traditional brushed motors. The BLDC winding machine is assigned with creating the coils that form the stator of these motors, which is a critical part of the motor’s performance.

The winding process in a BLDC motor is more intricate than in traditional motors. It requires precise control over factors similar as the number of coil turns, the winding pattern, and the pressure of the line to insure optimal electromagnetic characteristics. The BLDC winding machine is designed to perform this task with high delicacy, using automated controls to maintain thickness throughout the product process. With a machine that ensures perfection, manufacturers can produce high- quality brushless motors that deliver superior performance in a wide range of operations.

Robotization in Motor Winding with the Motor Winding Machine Automatic

The integration of robotization in the manufacturing process has significantly bettered motor product, particularly in the winding stage. The motor winding machine automatic plays a vital part in icing that the winding process is n’t only fast but also largely accurate. These machines are designed to handle the intricate winding of motor coils, whether they’re for small motors or large artificial machines.

Automated winding machines are programmed to perform specific tasks similar as conforming line pressure, winding speed, and the number of coil layers. This ensures that the coils are wound to exact specifications, which is essential for motor performance. With an automatic motor winding machine, manufacturers can achieve a position of perfection that’s delicate to replicate with homemade winding ways. This robotization reduces the liability of mortal error, which can lead to inconsistencies in coil conformation, potentially affecting the motor’s effectiveness and lifetime.

The part of the Brushless Motor Winding Machine

Another important development in motor manufacturing is the brushless motor winding machine, which is acclimatized to meet the specific conditions of brushless motors. As further diligence transition to brushless technology for its superior effectiveness and lower conservation requirements, the demand for technical winding machines has grown. The brushless motor winding machine is designed to accommodate the unique requirements of winding coils for these motors, which generally feature a more complex winding pattern than traditional motors.

The brushless motor winding machine operates with perfection, winding coils in a way that

Ensures optimal electromagnetic performance

This is critical because the effectiveness and performance of a brushless motor depend on the design and configuration of the stator windings. A well- wound coil allows the motor to operate more efficiently, reducing energy consumption and perfecting overall motor performance. By using a brushless motor winding machine, manufacturers can insure that their motors are erected to the loftiest norms of quality, which is particularly important in operations where trustability and effectiveness are consummate, similar as in electric vehicles and aerospace.

Perfecting Motor Design with Precision Winding Machines

The use of automated winding technology, particularly through the BLDC winding machine, has opened up new possibilities for motor design. These advanced machines allow for the creation of complex winding patterns that were preliminarily delicate to achieve with homemade processes. This perfection enables masterminds to design motors with optimized electromagnetic parcels, perfecting effectiveness and reducing energy loss.

By automating the winding process, manufacturers also have lesser inflexibility in their designs. The capability to fluently change winding patterns and configurations allows for the rapid-fire prototyping of new motor designs. This is pivotal in diligence where invention is crucial, similar as in the development of electric vehicles or renewable energy systems.

FAQs

1What’s a BLDC winding machine utilized for?

A BLDC winding machine is utilized to wind the coils for brushless DC( BLDC) engines. These machines safeguarded tall flawlessness and thickness in the winding handle, which is basic for the motor’s execution and adequacy.

2. How does the motor winding machine automatic ameliorate motor product?

The motor winding machine automatic automates the winding process, reducing the need for homemade intervention. This leads to briskly product pets, bettered delicacy, and harmonious coil conformation, eventually enhancing the motor’s performance.

3. What makes a brushless engine winding machine distinctive from other winding machines?

A brushless engine winding machine is particularly outlined to meet the prerequisites of winding coils for brushless engines. It accommodates the complex winding patterns needed for these motors, icing optimal electromagnetic performance and effectiveness.

4. How do BLDC winding machines impact motor effectiveness?

BLDC winding machines insure that the coils in brushless motors are wound with high perfection, which directly improves the motor’s electromagnetic parcels. This results in better effectiveness, lower energy loss, and longer motor lifetime.

Conclusion

The use of BLDC winding machines, motor winding machine automatic, and brushless motor winding machines has played a vital part in enhancing the performance and effectiveness of ultramodern motors. By automating the winding process, manufacturers can achieve advanced perfection, reduce product times, and insure harmonious quality. As technology continues to evolve, these machines will remain at the van of motor manufacturing, driving inventions in motor performance and contributing to the success of diligence around the world.