The Role of Rapid Prototyping in Manufacturing

Rapid prototyping has become an integral yet essential part of modern manufacturing. How so, you may wonder? The manufacturing world is on an upward trajectory when it comes to innovating and developing cutting-edge products.

Equally, rapid prototyping isn’t just a tool for the manufacturer to showcase its competence and expertise but a canvas for engineers and designers to display their technical skills.

It is cardinal for us to explore its manifold applications across different industries during this expedition. In addition, the beneficial attributes of rapid prototyping, such as cost reduction, will reveal to us why manufacturers crave this genius technique. So, buckle up and enjoy the trip.

Overview of Rapid Prototyping

For a proper understanding of rapid prototyping service, let’s shed more light on the subject. Rapid prototyping is responsible for concept visualization. Before full commitment is devoted to a project, especially a newly developed one, a sample is needed. This sample is then iterated, enhanced, and modified to fit all the required features and performance expected of the product. Moreover, since engineers and designers are craftsmen, they decide what technology best suits the rapid prototyping process before commencing mass production.

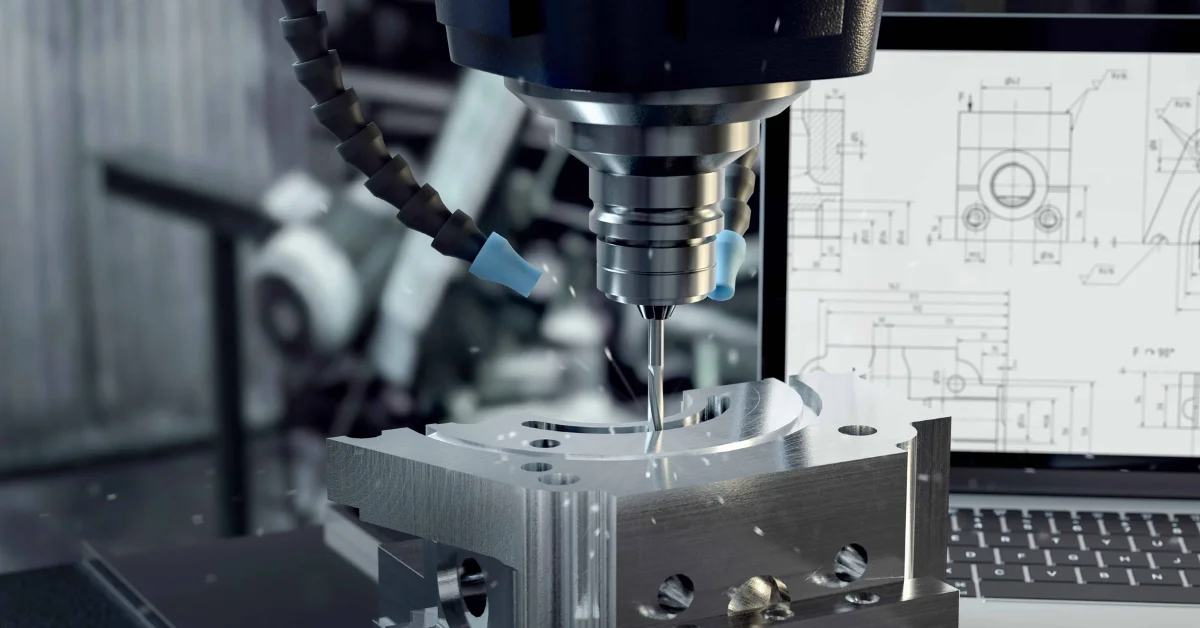

A typical example is the use of CNC machining which creates a prototype from a block of material and is able to reveal performance flaws in a prototype. 3D printing on the other hand builds a prototype layer by layer with utmost precision. This technology can also expose configurational defects. Injection molding when employed simulates the structural and functional properties of the product models.

These technologies foster the implementation of modifications and corrective measures in both physical and virtual models thus allowing rapid prototyping to create a trustworthy channel to innovative products. In essence, rapid prototyping shortens the time-to-market cycles with the validation of the product models and this in turn reduces cost. Let’s examine more of the benefits of rapid prototyping.

Advantages of Rapid Prototyping

Shortening Development Cycles

Often for companies with robust innovative capacities, several ideas and designs are ready to be out the door and into the market. But how do they scale above the red tape of impending flaws and defects? That is the major aim of rapid prototyping. This enables companies to transition fast from idea to product in a short period. Moreover, with the advent of extraordinary technologies to help reduce the development cycle, rapid prototyping can accelerate the fabrication of prototypes for necessary modifications to be applied. When you have technologies such as CNC machining and 3D printing, create a shortcut to launching new ideas faster than expected.

Cost Reduction

Nobody loves cost reduction more than a company trying to launch a brand-new product without suffering setbacks. The idea of reducing cost in production also extends to other factors. They are not limited to but include incurring unnecessary extra costs, especially in tooling and materials, time wastage, and inefficient distribution of resources. All of which leads to increased cost of production. With this in mind, rapid prototyping assists in eliminating all of these concerns. Furthermore, when prototypes are constructed the elimination and preservation of components that will allow the product’s success will be employed. This cancels out unintended costs while saving time and resources.

Encouraging Innovation and Customization

With the idea of rapid prototyping service, innovation, and customization is heightened. Fresh ideas are often developed at the prototyping stage and also at iteration and modification stages. The concept of rapid prototyping likewise inspires customization. Stakeholders in the designing process are emboldened to put on their creative caps to envision and create ground-breaking components.

Improving Quality and Precision

In addition to all the previously outlined benefits of rapid prototyping, a crucial incentive to this concept is the boost in quality the developed product receives. Rapid prototyping ensures that the appearance and performance of the product are in top form and efficiently crafted. With that, when such a product is launched, the company retains the trust of its customers while acquiring more. Talk about a quality-assured product, then rapid prototyping is the way to go.

Applications of Rapid Prototyping across Industries

Consumer Electronics

If you’ve been following us intently, we mentioned earlier the vastness of the application of rapid prototyping cutting across numerous industries. One such is the consumer electronics industry where injection molding finds extensive application. A lot of our home appliances, gadgets, and outdoor appliances are beneficiaries of the rapid prototyping concept.

Manufacturers of consumer electronics have been able to leverage the prowess of rapid prototyping to serve their consumers with top-functioning and aesthetically pleasing electronics. A very good example of such is the smartphone market. Different brands offer different features in their smartphones that appeal to different demographics and styles. All testify to the fast-tracking speed of rapid prototyping to satisfy consumers.

Automotive and Aerospace

Let’s take a magnifying look at the automotive and aerospace industry. This industry considers safety a priority, hence their massive reliance on rapid prototyping to design the best components. The application of rapid prototyping in the automotive industry encompasses both the interior and under-the-hood components.

Prototypes are developed when testing for functionality and durability. This ensures automobile drivers are safe and satisfied with their automobiles. Specifically, the engines and interior components undergo rigorous safety and performance tests. Similarly, the aerospace industry employs rapid prototyping to ensure ultimate performance and structural capacity is at its peak.

Medical Devices

In the medical world, patient safety is of utmost importance. For this reason, medical devices are crafted to suit every patient’s health needs. Rapid prototyping service has contributed immensely to the realization of such conditions. Devices such as prosthetics and surgical instruments are designed with creative iterations for optimal performance.

Other Industries

Other industries make the best use of rapid prototyping to reduce cost and ensure its presentation is pleasing. The resourcefulness of rapid prototyping is also encountered in the manufacturing of industrial equipment, appliances, and toys. Heavy-duty industrial equipment is adjusted to perform excellently. Gadgets and home appliances are likewise upheld to maintain safety and functionality.

Conclusion

To crown it all, rapid prototyping in modern manufacturing has held its own by encouraging innovation in many industries. With rapid prototyping, engineers and designers are empowered to create masterpieces in product design and development.

Furthermore, rapid prototyping has invented a reduction in cost, efficient distribution of materials, and effective time management. This in turn ensures manufacturers can leverage its prowess. On top of that product quality is enhanced, performance and presentation also.

Still, advancements in technology are liable to open doors of unimaginable possibilities for smarter product testing and modification while meeting consumer needs.

Stay in touch to get more updates & alerts on VyvyManga! Thank you